Market Research Industry Today

3D Printing Market Report 2025 Edition: Industry Size, Share, Growth and Competitor Analysis

Market Overview:

IMARC Group has recently released a new research study titled “3D Printing Market Report by Technology (Stereolithography, Fused Deposition Modeling, Selective Laser Sintering, Electron Beam Melting, Digital Light Processing, and Others), Process (Binder Jetting, Directed Energy Deposition, Material Extrusion, Material Jetting, Powder Bed Fusion, Sheet Lamination, Vat Photopolymerization), Material (Photopolymers, Plastics, Metals and Ceramics, and Others), Offering (Printer, Material, Software, Service), Application (Prototyping, Tooling, Functional Part Manufacturing), End-User (Consumer Products, Machinery, Healthcare, Aerospace, Automobile, and Others), and Region 2025-2033”, The study provides a detailed analysis of the industry, including the global 3D printing market trends, growth, size, and industry trends forecast. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How Big Is the 3D Printing Market?

The global 3D printing market size was valued at USD 28.5 Billion in 2024. Looking forward, IMARC Group estimates the market to reach USD 125.9 Billion by 2033, exhibiting a CAGR of 17.9% during 2025-2033. North America currently dominates the market, holding a significant market share of over 33.8% in 2024. The market is primarily influenced by the continual advancements in AI-powered 3D printing technologies, increasing reliance on personalized solutions in numerous end-use industries, rising adoption of sustainable manufacturing methods, and strategic government initiatives facilitating additive manufacturing.

Request to Get the Sample Report: https://www.imarcgroup.com/3d-printing-market/requestsample

3D Printing Market Trends: 2025 Outlook

The 3D printing market is entering a pivotal stage of maturity and expansion, powered by next-generation materials, integrated digital workflows, and growing industry-wide adoption. As the need for agile, sustainable, and customizable manufacturing intensifies, additive manufacturing (AM) is evolving into a mainstream solution across sectors including healthcare, aerospace, automotive, and consumer goods.

By 2025, the convergence of 3D printing with AI, robotics, and cloud-based platforms is revolutionizing how products are designed, produced, and delivered. Healthcare is advancing toward patient-specific bioprinting and medical device innovation, while aerospace and automotive sectors continue to push the limits of lightweight, high-strength component manufacturing. Meanwhile, rising environmental awareness and reshoring strategies are reinforcing the value of on-demand, localized, and resource-efficient production.

With its ability to reduce waste, lower inventory costs, and unlock unprecedented design freedom, 3D printing is no longer a niche technology—it is fast becoming a cornerstone of future-ready manufacturing ecosystems.

Key Market Dynamics Driving Growth

- Evolution of Advanced Materials and Sustainable Feedstocks

Material innovation remains at the forefront of 3D printing’s growth. The development of high-performance, application-specific materials—ranging from high-temp thermoplastics and advanced metal alloys to ceramic and bio-based resins—is enabling more demanding and high-precision applications.

In 2025, we’re witnessing a surge in demand for sustainable and circular materials, such as recycled polymers and biodegradable composites, aligning with global ESG goals. Additionally, innovations in smart materials—those that respond to stimuli such as heat or pressure—are opening new opportunities in electronics, wearables, and biomedical devices.

The growing compatibility of 3D printers with multi-material formats is accelerating hybrid printing, allowing manufacturers to produce multifunctional parts in a single pass and reducing the need for assembly. These breakthroughs are expanding AM’s potential across industries, from custom consumer products to mission-critical aerospace components.

- Integration with AI, Robotics, and Smart Manufacturing

Additive manufacturing is increasingly becoming part of the broader Industry 4.0 ecosystem. The integration of AI and machine learning into 3D printing workflows is enabling real-time design optimization, defect prediction, and adaptive quality control. These technologies are transforming the AM process from trial-and-error to a predictive, autonomous system.

In 2025, robotic automation is enhancing pre- and post-processing stages—automating everything from material loading and part removal to surface finishing. Meanwhile, cloud-based collaboration platforms and digital twins are streamlining remote design and production monitoring.

Together, these advancements are increasing scalability, reducing lead times, and making decentralized, lights-out manufacturing a reality. For manufacturers, the synergy of AI, robotics, and additive technologies offers a path to higher productivity, lower operational risk, and more agile supply chains.

- Healthcare Leads Adoption with Personalized, On-Demand Solutions

The healthcare sector continues to be a leading force in the adoption of 3D printing, driven by the growing demand for hyper-personalized care. From dental aligners and prosthetics to surgical guides and orthopedic implants, additive manufacturing is enabling customized, patient-specific solutions that improve clinical outcomes and lower costs.

By 2025, bioprinting is moving closer to clinical application, with major advancements in 3D-printed tissues and organ scaffolds. Regulatory bodies are streamlining approvals for 3D-printed medical devices, creating a more supportive environment for innovation. Hospitals and surgical centers are increasingly setting up in-house 3D printing labs for real-time prototyping and surgical planning, reducing dependency on external suppliers.

As digital health, wearable devices, and AI-driven diagnostics evolve, the intersection of these technologies with 3D printing is driving a more integrated and data-informed approach to healthcare delivery.The 3D printing market is transitioning from experimentation to industrialization. As it becomes deeply embedded in smart manufacturing strategies, its impact is being felt across design, production, and distribution channels. In 2025, additive manufacturing is no longer just about prototypes—it’s about precision, personalization, and performance at scale. Companies that invest in material innovation, digital integration, and sustainable practices will be best positioned to lead in the additive-first future.

Buy Now: https://www.imarcgroup.com/checkout?id=1325&method=1670

3D Printing Market Report Segmentation:

Breakup Technology:

- Stereolithography

- Fused Deposition Modeling

- Selective Laser Sintering

- Electron Beam Melting

- Digital Light Processing

- Others

Based on the technology, the market has been divided into stereolithography, fused deposition modeling, selective laser sintering, electron beam melting, digital light processing, and others.

Breakup By Process:

- Binder Jetting

- Directed Energy Deposition

- Material Extrusion

- Material Jetting

- Powder Bed Fusion

- Sheet Lamination

- Vat Photopolymerization

Binder jetting dominates the market due to its high speed, cost-effectiveness, and ability to produce large-scale parts with minimal waste, making it ideal for industrial applications.

Breakup By Material:

- Photopolymers

- Plastics

- Metals and Ceramics

- Others

Photopolymers represent the majority of shares as they are widely used in additive manufacturing for producing detailed, high-resolution parts, especially in industries like healthcare and automotive.

Breakup By Offering:

- Printer

- Material

- Software

- Service

Printers hold the majority of shares because the growing adoption of 3D printing technology across various industries drives demand for high-performance, innovative printing hardware.

Breakup By Application:

- Prototyping

- Tooling

- Functional Part Manufacturing

Prototyping exhibits a clear dominance as 3D printing is most commonly used for rapid prototyping, allowing for quick design iterations and cost-effective product development.

Breakup By End-User:

- Consumer Products

- Machinery

- Healthcare

- Aerospace

- Automobile

- Others

Consumer products hold the majority of the market share due to the increasing use of 3D printing for creating customized goods, from home décor to personalized electronics and fashion accessories.

Breakup By Region:

- Europe

- North America

- Asia Pacific

- Middle East and Africa

- Latin America

North America holds the leading position owing to its advanced technological infrastructure, significant investment in research and development (R&D), and strong presence of leading 3D printing companies.

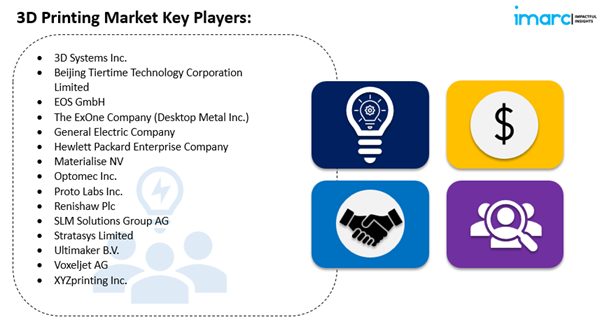

Top 3D Printing Market Leaders:

The 3D printing market research report outlines a detailed analysis of the competitive landscape, offering in-depth profiles of major companies.

Some of the key players in the market are:

- 3D Systems Inc.

- Beijing Tiertime Technology Corporation Limited

- EOS GmbH

- The ExOne Company (Desktop Metal Inc.)

- General Electric Company

- Hewlett Packard Enterprise Company

- Materialise NV

- Optomec Inc.

- Proto Labs Inc.

- Renishaw Plc

- SLM Solutions Group AG

- Stratasys Limited

- Ultimaker B.V.

- Voxeljet AG

- XYZprinting Inc.

Ask Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=1325&flag=C

Key Highlights of the Report:

- Market Performance (2019-2024)

- Market Outlook (2025-2033)

- Market Trends

- Market Drivers and Success Factors

- Impact of COVID-19

- Value Chain Analysis

If you need specific information that is not currently within the scope of the report, we will provide it to you as a part of the customization.

About Us

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARC’s information products include major market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the company’s expertise.

Contact Us:

IMARC Group

134 N 4th St

Brooklyn, NY 11249, USA

Website: imarcgroup.com

Email: sales@imarcgroup.com

Americas: +1-631-791-1145

Share on Social Media

Other Industry News

Ready to start publishing

Sign Up today!